Do it yourself: Points Mag Rev Limiter

If you run a Super-Mag, Sprintmag or Vertex points-style magneto, you may wish you had a top end rev limiter. In some applications, it would be great if you had a launch rev limiter and maybe even a burn out rev limiter as well. You can put together a very solid rev limiter for your magneto by connecting a few common gadgets...some of which you may already have laying around.

You might remember the Autometer Pro-Control. The Pro-Control model that racers used with magnetos is no longer built, but it was basically an RPM activated switch with a relay that turned things ON or OFF. By hooking up the normally open terminal to the magneto and the common terminal to ground, it was easily turned into a rev limiter just like the contraption covered here. Unfortunately, the small relay in the Pro-Control couldn't handle the full output of most magnetos for very long. After hitting the rev limiter a few times, it was usually smoked. We can do better than that!

A basic rev limiter system is made up of three different functions. A device to kill the magneto, a device to make the kill-decision and something to generate a pulse signal that reflects engine speed...

The Killer

To kill your points style magneto when the time comes, we're going to ground it. The challenge here is to ground it using something that can take the repeated abuse of all that primary voltage and current. It also needs to resist vibration so it won't short the ignition when you DON'T want it to. We have just the thing: the FIE RPM Limit Relay. It's a super-capable, high current/high voltage relay that we wire and package for reliable service and long life. When the RPM limit is reached, the relay closes, the mag is killed and the RPM drops allowing the engine the resume running. If you keep your foot in it, it will quickly oscillate ON and OFF and sound similar to a "soft touch" type limiter. Since sparks are taken, the engine is left rich and safe during limiting. Only high volume nitro motors will have trouble when grounding the ignition. Methanol folks will be just fine...there won't be enough liquid in the cylinders to cause a hydraulic lock situation.

When limiting an external coil style magneto, you'll use the positive and negative coil terminals as your attachments. If your magneto is an internal coil (OAC) Vertex, this limiter works for you too! You'd simply use the primary side terminal on the mag as positive from the relay. Instead of attaching the black wire to the negative coil terminal, you'll just attach it to engine ground.

Listen and Decide

Since the relay will do the "heavy lifting" task of killing the magneto, we need some adjustable logic to figure out when to activate it for us. An RPM activated type switch is needed and the MSD 8950 works great for this task. It accepts standard MSD RPM modules (chips) so you can easily adjust it to act when you want. This particular device works by switching ground ON with its yellow wire. That means when the time comes, it completes the circuit to ground to the device it's controlling and the controlled device must be connected to 12VDC all the time for this to work. The RPM activated switch monitors the frequency of the engine speed pulse and makes the decision for us. Instead of using a module in the RPM activated switch, you could use the MSD 8739 2-step module selector to switch between two different RPM limits with your rev limiter. All we need now is a pulse to make our rev limiter complete...

Check Your Pulse

Unfortunately, we can't really use a pulse from the ignition itself to sense engine speed. The problem with that is when we kill the magneto at rev-limit time, the speed pulse we're monitoring suddenly ceases to exist and behavior can be erratic at best. So, we need a separate speed sensitive signal to monitor and evaluate. Crank trigger pickup to the rescue! The easiest, most basic way to get a speed signal from the engine is to use a flying magnet style trigger wheel and pickup. Many companies make complete kits with wheel, bracketry and pickup to fit your application. In the case of supercharged motors, you may just need to add a magnet ring to your hub, put the correct bracket and holder on your motor and you're in business. A pickup used for a rev limiter does not need to be adjustable, so nothing fancy is required here. It doesn't matter where the pulses happen, we just need the pulses to count the frequency to determine engine speed. FIE manufactures a fully shielded pickup for a very reliable, noise-free signal. Most pickups out there should work ok for this task unless you run solid core spark plug wires. Solid core wires induce a lot of noise in everything and shielding the speed signal as best you can will be important in that case. A noisy, polluted signal will always cause the rev limiter to limit TOO EARLY. The noise is counted as extra pulses and it thinks the motor is going faster than it really is. A shielded pickup and suppression core plug wires (50 ohms/ft or less) are your best bet for a rev limiter that works perfectly.

UPDATE!!!

If you use some kind of offset drive or front drive (not a standard straight drive or a Vertex), you're probably going to have to go with the crank trigger option.

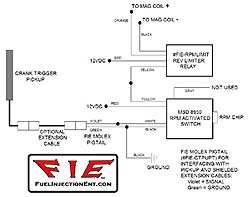

The FIE Kill relay mentioned above also includes a Molex pigtail to make it easy to wire things up to your crank trigger pickup. A pickup will usually have two leads, a ground (green or black) and the signal (clear, white, or violet). The signal goes into the RPM activated switch to be evaluated. The switch does its thing when the pre-set speed is reached and the relay is turned on which grounds the mag. Limiting happens only while the engine speed is at or above the preset level. See the schematic here for how it all goes together. Here's the PDF version. Links in this article will lead you to some of the components needed for this project, available on our webstore. If your RPM switch is a distance away from your pickup, you should consider using a shielded extension cable to keep your signal pure.

Here's something you should know about rev limiters of any kind. An engine is a rotating mass of heavy parts and pieces. If your engine is pulling hard against a load and something in the drivetrain were to break, the suddenly freed engine is going to continue to spin a bit faster even if you're quick with the throttle. If you're close to your desired rev limit and this happens, you've got to assume that even though your ignition is off as planned, your parts are going to continue a bit above your desired level. While the rev limiter isn't absolute insurance against spinning faster than a particular defined engine speed, it will certainly keep things in check by defeating the ignition there and not allowing things to get out of control.